-

All American Electric Steam Sterilizers, models 25X, 50X & 75X. These units are available in either 120 or 240 volts. One of the most important things to note is that the 25X Electric Steam Sterilizer uses a 1050 watt heating element while the other units (The 50X and 75X) each have a 1650 watt heating element. The Model 50X and 75X uses a 1650 watt heating element. This increased wattage and heating capacity means that the units will get up to operational temperature far quicker than the 25X. Plus, the 50X & 75X have all new electrical controls as well as a new thermostat which is designed to hold a much tighter operating band. Therefore there will be less variation as the thermostat turns the heating element on and o ffto maintain a certain level of heat. All American steam sterilizers are used world-wide to sterilize a wider range of materials. Temperature, pressure and time are the main factors in this process. All American Sterilizers make in possible for doctors, dentists, first aid stations, hospitals, laboratories and of course, mycologist to have dependable sterilization facilities in a portable unit at an extremely lowcost. Features: Portable, Economical, Reliable Operation Metal to Metal Seal The metal to metal seal eliminates all rubber gaskets. Pressure Gauge Accuracy Pressure Relief Valve UL Approved Heavy cast aluminum cover and bottom construction Aluminum inner container with rack Flexible metal exhaust tube Dial gauge and control valve Metal-to-metal seal (no rubber gasket) Large sterilizing capacity Complete, effective sterilization at the lowest possible cost Individual corrugated carton packaging

All American Electric Steam Sterilizers

-

LDF series waste incinerator adopt gasification combustion that can make garbage more sufficient burning. Waste incinerator is a kind of machine that possess the own intellectual property, features unique and advanced merits with compact size, high burning efficiency, reasonable burning technology, high degree of non-harm etc, it is an ideal choice for waste treatment of hospital, hotels, various stations and industries. Features: Both gas-motivated and oil-motivated are all can be preferred according to customers’ needs. Gasified incineration is used for burning syringe, paper waste, bandage, absorbent cotton and other medical wastes. Daily waste can be burned once by gasified incineration. Gasified incineration, mixed incineration and burnout treatment ensures low emission standard of dust (lower than International standard). Totally enclosed operation is suitable for treating infectious waste to avoid secondary pollution. Advantages: Long lifetime Totally enclosed operation Suitable for treating infectious waste Avoid secondary pollution Simple operation Smokeless and no harmful to environment Continuously and fully burning Simple operation Incinerator LDF-100 Parameter: Applicable hospital size 250 beds Max. Burning Ability 100 kg/time Size of the Burner 1.5m×1.15m×3m Volume of the Burner Gasification room 0.5m3 second buming room 0.3m3 Chamber Temperature First chamber:600℃-700℃; second chamber:300℃-1300℃ Ash residue ≤5% Size of the filling entrance 620mm×800mm Chimney Hight 10m,Out-radiusØ300 Blower 0.37kw Auxiliary machine Power0.11kw,fuel consumption4-10kg/h Re-burning machine Power0.11kw,fuel consumption6-10kg/h Running voltage 220V or 380V Weight About 4600(kg) Flue&Gas Emission Standards: OrdinalNumber Refuse name Measuring unit GB18484-2001 1 Blackness of Flue Ringelmann class 1 Gas 2 Smoke&Dust mg/m3 100 3 CO mg/m3 100 4 SO2 mg/m3 400 5 HF mg/m3 9.0 6 HCL mg/m3 100 7 NO2 mg/m3 500 Click Here To Download Catalogue

Medical Waste Incinerator (Capacity – 100Kg)

-

TBT designed a full range of steam and low temperature sterilizers for specific uses in various fields including hospitals & clinics, laboratories, research centers, and industry. All TBT sterilizers combine technological advances together with safety and quality in order to offer a reliable and efficient solution which also cares about environmental standards. The complete range is designed to provide a cost-effective solution through the process flow starting from procurement of devices and ends with continuous operating of sterilizers in CSSDs, clinics, laboratories, and industry. PLUSTEAM Series Steam Sterilizers are designed in accordance with the needs of clinical experts in order to deliver the highest performance with cost efficiency. PLUSTEAM Series Steam Sterilizers cover a wide range starting from 102 L (1 STU) to 988 L (14 STU). Wide range of accessories and optional features enable each device to be tailor fit for the needs of clinic. Click Here To Download Catalogue

Steam sterilizer PLUSTEAM

-

Closed Door Active Drying Air Pump: With extra fast and efficient drying cycles, the EKA and EA autoclaves significantly increase your productivity. These two models h ave the added benefit of a high efficiency air pump which allows closed door active drying. The EKA and EA are built for improved sterilization with the ability to dry packs and pouches. Benefits: More thorough drying and sterilization Faster drying for a shorter overall cycle 0.2 µm HEPA air filter provides sterile, bacteria-free air for drying Model Chamber Volume Cold Cycle Time Hot Cycle Time EA Series 2340EA 19 Liter 23 min. 16 min. 2540EA 23 Liter 25 min. 18 min. 2850EA 64 Liter 31 min. 20 min. 2870EA 85 Liter 31 min. 20 min. EKA Series 2340EKA 19 Liter 14 min. 11 min. 2540EKA 23 Liter 14 min. 11 min. -Tested for unwrapped instruments. Cycle times includes heatup, sterilization exposure and exhaust. All cycle times may vary with instrument load and voltage.

Tuttnauer

-

Model Chamber Volume Cold Cycle Time Hot Cycle Time EA Series 2340EA 19 Liter 20 min. 12 min. 2540EA 23 Liter 22 min. 14 min. 3140EA 34 Liter 25 min. 17 min. 3850EA 64 Liter 31 min. 17 min. 3870EA 85 Liter 29 min. 20 min. EKA Series 1730MK (Valueklave 7.5 Liter 12 min. 9 min. 2340EKA 19 Liter 12 min. 9 min. 2540EKA 23 Liter 12 min. 9 min.

tuttnauer Chamber Models

-

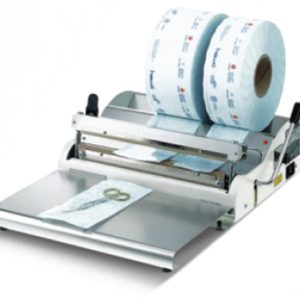

Sterilization is effective only if the sterility of the instruments is preserved from the point of sterilization until they are used. The sealing process ensures that the instruments remain sealed after sterilization and maintain perfect sterility during their Automatic night mode shuto ffis a time and energy saver shelf-life. Our range of fast and reliable impulse sealers complies with the strictest quality and safety standards (DIN 58953-7). For rapid instrument turnaround we offer an automated range of rotary sealing machines.

tuttnauer Impulse Sealing Machines

-

Featuring Tuttnauer’s range of cleaning, disinfection and sterilization solutions

Tuttnauer Large sterilizers for various industries and market needs

Zenrox Healthcare Solutions - Advanced Medical Equipment in Lagos

Zenrox offers cutting-edge medical equipment and comprehensive support services in Lagos. Explore our products designed for superior healthcare delivery. Contact us today for innovative medical solutions.